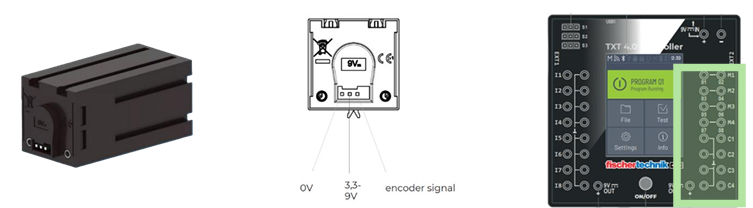

ENCODER MOTOR 9V

Programming Blocks

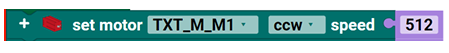

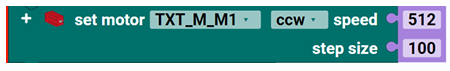

| Block | Function |

|---|---|

|

The motor will set its direction (CW or CCW) and its speed (between 0 and 512), then start to turn. |

|

The motor sets its direction (CW or CCW) and speed (from 0 to 512), then rotates for the number of steps you provide (every 100 steps equals one and one-third rotation). |

|

The motor stops. |

|

Check if the motor has reached its target position. |

Electrical characteristics

| Motor | |

|---|---|

| Voltage Suggested | 9.0 DC Constant between motor terminals |

| Operating Temperature Range | Between 0ºC to +50ºC |

| Storage Humidity Range | Between 20% to 70% |

| Reduction Ratio | 1:21.3 |

| No Load Speed | 280(±35) rpm |

| No Load Current | 0.18A max. |

| Stall Torque | 2.5 kgcm min. |

| Stall Current | 3.0 A max. |

| Encoder | |

|---|---|

| Signal | Push-Pull Output (0/9V), max. 10 mA |

| Frequency | max. 1 kHz |

| Connector | 3-pin header |

| Fitting Cable | Art. Nr. 137125, Art. Nr. 168961 |

| Supply Voltage Encoder | 3.3 – 9V DC |

| Signal | npn open collector output, max. 2 mA |

| Resolution | 3 pulses per round of motor. 63.9/127.8 pulses per round of the gear shaft. |

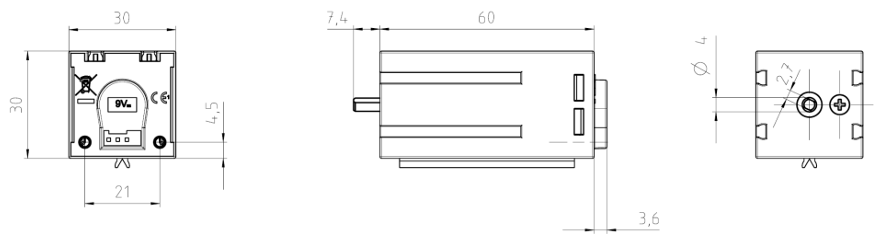

Dimensions

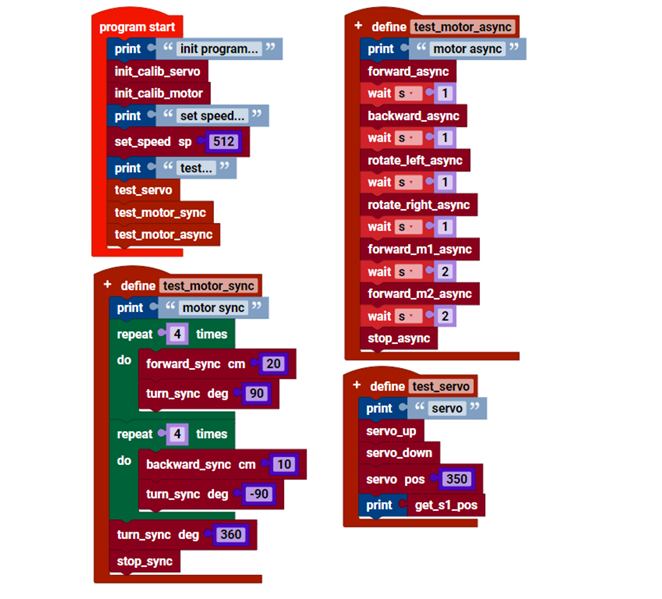

Sample Code

Result: The Encoder Motor will start to turn counter-clockwise for 100 steps at speed 512 (Maximum speed), and after 3 seconds, it will start to turn clockwise for 50 steps at speed 250, and then after 3 seconds, the program will repeat again.

Motor Speed Limits

In the ROBO Pro Coding App, the motor speed input must be within the range of 0 to 512. However, when the speed is controlled by a variable, it is possible to generate a value outside this range. If the motor receives a value that is out of range, the program will stop. To prevent this, you can either use an if-else check to manually limit the value, or use the constrain block to automatically keep the speed within the allowed range. This ensures the motor always runs with a valid speed. Below, you can compare both methods.

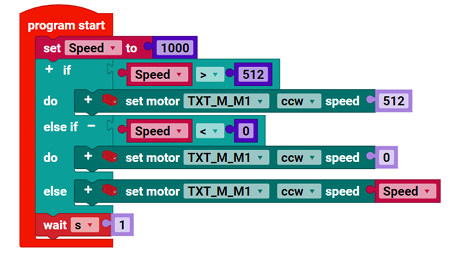

If-else Check

In this example, the variable Speed is set to 1000 at the start, which is outside the valid motor speed range of 0 to 512. To handle this, the program uses an if–else structure to limit the value before sending it to the motor.

• If Speed is greater than 512, the motor will run counterclockwise with a speed of 512.

• If Speed is less than 0, the motor will run counterclockwise with a speed of 0.

• Otherwise, the motor will run counterclockwise with the value stored in Speed.

This way, the motor always receives a valid speed, even when the variable goes out of range.

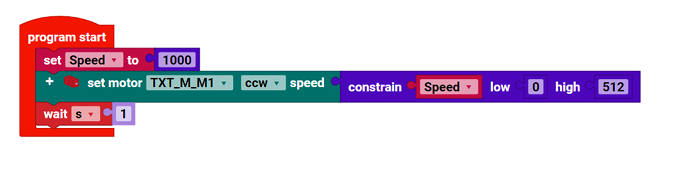

Constrain Block

The program uses the constrain block to make sure the motor speed stays within the allowed range of 0 to 512. Even though the variable Speed is set to 1000, the constrain block limits this value to 512 before sending it to the motor. This ensures the motor always receives a valid speed without needing multiple if-else checks.

Motor Control Library

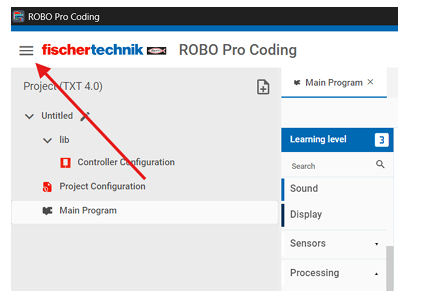

- Open the Robo Pro Coding app.

- Tap the three-line menu icon in the top-left corner.

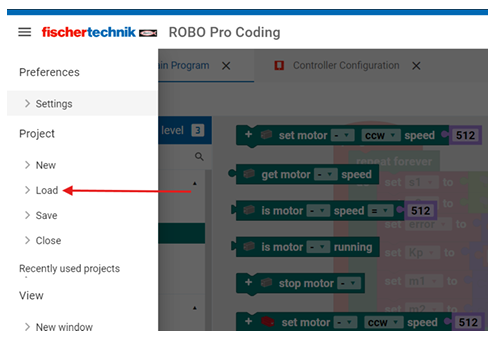

- Select load from the menu.

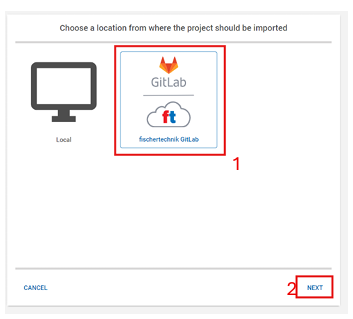

- Choose Fischertechnik GitLab, then click Next twice (after first click the instructions for using GitLab will be shown in a popup).

- In the search bar, type "motor_servo", select the appropriate library from the results shown below, and then click Import.

- Now you can see the Synced motor codes library for moving forward straightly or turning for a specific angle.